- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Why Rapid Prototypes Are Revolutionizing Product Development

2025-08-15

In today’s fast-paced market, Rapid Prototypes have become a game-changer for businesses looking to innovate quickly and efficiently. Whether you're in automotive, aerospace, medical, or consumer electronics, rapid prototyping accelerates design validation, reduces costs, and shortens time-to-market. But what exactly makes this technology indispensable?

The Power of Rapid Prototyping: Speed Meets Precision

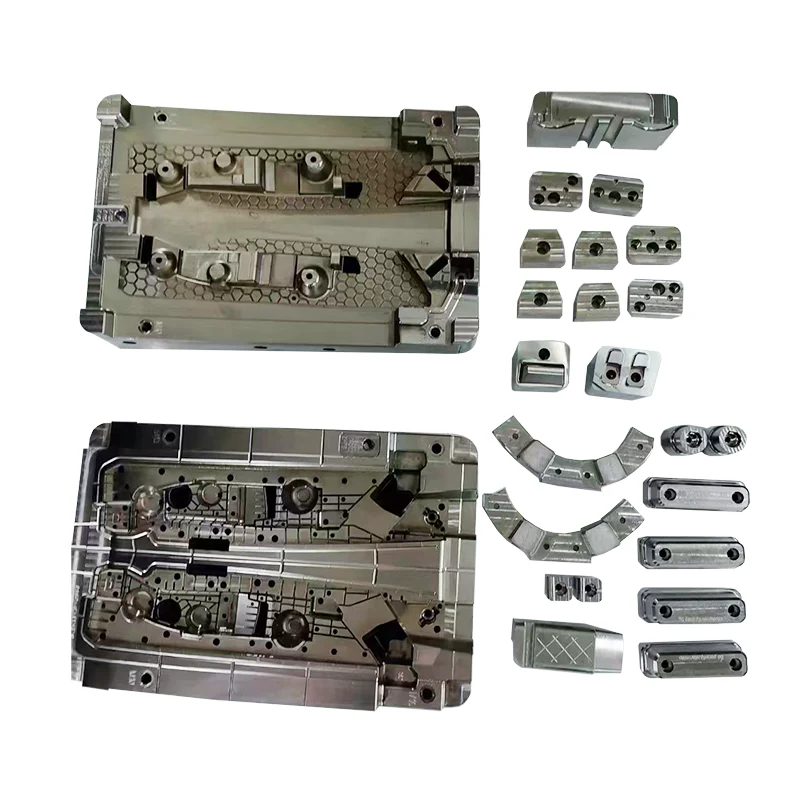

Rapid prototyping leverages advanced technologies like 3D printing, CNC machining, and vacuum casting to transform digital designs into physical models within hours—not weeks. This speed enables engineers and designers to test functionality, aesthetics, and ergonomics early in the development cycle, minimizing costly revisions later.

Key Benefits:

Faster Iterations – Test multiple designs in days instead of months.

Cost Efficiency – Avoid expensive tooling changes with early-stage adjustments.

Customization – Easily modify designs for niche applications.

Risk Reduction – Identify flaws before mass production.

How Rapid Prototyping Works: Technologies Compared

Not all prototyping methods are the same. Below is a quick comparison of the most widely used techniques:

| Technology | Materials | Best For | Lead Time |

|---|---|---|---|

| 3D Printing | PLA, ABS, Resin, Metal | Complex geometries | 1-3 days |

| CNC Machining | Aluminum, Steel, Plastic | High-precision parts | 2-5 days |

| Vacuum Casting | Silicone, Urethane | Small-budget production | 3-7 days |

Each method has its strengths, and choosing the right one depends on your project’s requirements.

Rapid Prototypes: Common Questions Answered

Q1: What’s the typical turnaround time for a rapid prototype?

A: Depending on complexity and technology, most prototypes are delivered in 1-7 days. 3D printing is the fastest (1-3 days), while vacuum casting may take longer due to mold preparation.

Q2: How accurate are rapid prototypes compared to final products?

A: Modern prototyping methods achieve ±0.1mm tolerance, making them nearly identical to production parts. However, material properties may differ slightly in 3D-printed models.

Why Choose Mudebao for Your Prototyping Needs?

At Mudebao, we specialize in high-quality Rapid Prototypes tailored to your exact specifications. Our state-of-the-art facilities support 3D printing, CNC machining, and vacuum casting, ensuring your product moves from concept to reality seamlessly.

Why Partner with Us?

Expert Team – 20+ years of industry experience.

Fast Turnaround – Get prototypes in as little as 24 hours.

Competitive Pricing – No hidden costs, just precision and speed.

Contact Us today to discuss your project requirements and get a free quote!