- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Industry News

How Are Magnesium CNC Parts Manufactured to Meet Precision Engineering Demands?

Magnesium CNC parts refer to components machined from magnesium alloys using computer numerical control (CNC) processes. These parts are widely applied in industries that require strict dimensional accuracy, weight optimization, and repeatable quality, such as aerospace, automotive engineering, medi......

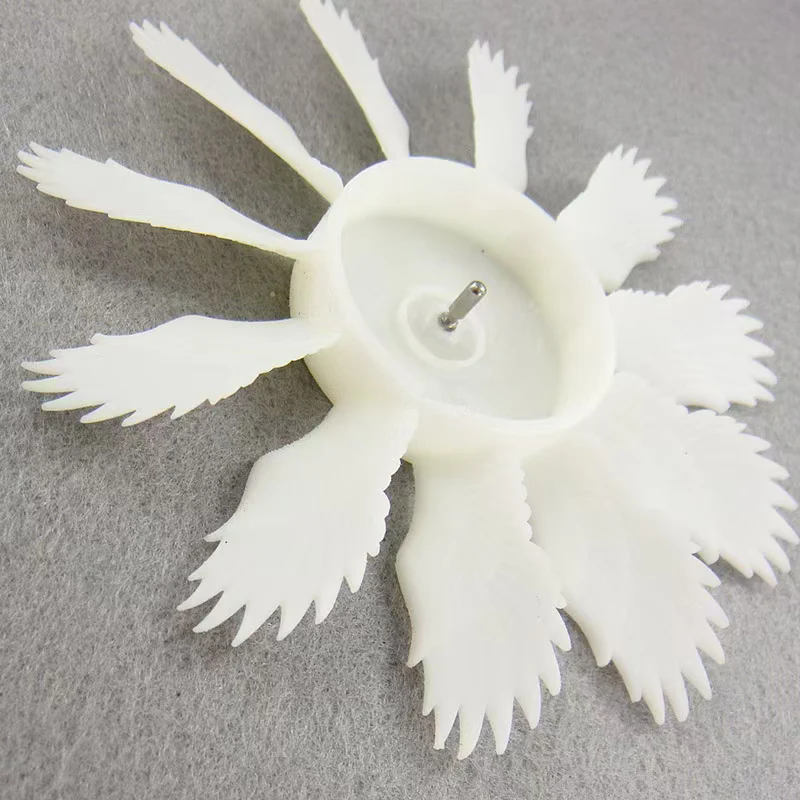

Read MoreHow Does the Urethane Casting Process Deliver High-Precision, Low-Volume Manufacturing Advantages?

The urethane casting process—also known as vacuum casting—has become one of the most dependable solutions for producing high-quality, low-volume parts with exceptional accuracy. It bridges the gap between rapid prototyping and full-scale injection molding, giving manufacturers a cost-effective metho......

Read MoreHow Do Wear Plates Transform Industrial Durability and Future Performance?

Wear plates are engineered protective components designed to resist abrasion, impact, heat, and chemical corrosion in demanding industrial environments. They function as sacrificial surfaces installed on equipment to extend service life, reduce operational downtime, and optimize long-term maintenanc......

Read MoreWhy Are Ejector Pin and Ejector Sleeve Essential for High-Precision Mold Performance?

In modern injection molding, the stability, durability, and precision of Ejector Pin and Ejector Sleeve components directly influence mold service life and product quality. These two components may appear simple, yet they play a critical role in ensuring molded parts are released smoothly, efficien......

Read MoreWhy Are Rapid Prototypes Essential for Modern Product Development?

In today's accelerated manufacturing world, Rapid Prototypes play a critical role in shortening development cycles, lowering project risks, and improving design accuracy. By converting ideas into physical models within days, engineers and manufacturers can identify structural issues early, validate......

Read MoreWhy Moldbase and Standard Part Are Essential for Efficient Production

When I first started working in mold production, I quickly realized how much of a difference high-quality Moldbase and Standard Part make in daily operations. At Moldburger, we pride ourselves on providing reliable components that not only increase efficiency but also reduce downtime in mold manufac......

Read More