- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Why Are Rapid Prototypes Essential for Modern Product Development?

2025-09-05

In today’s highly competitive market, businesses face constant pressure to innovate faster, reduce costs, and deliver products that meet evolving customer expectations. One key technology that has transformed the product design and manufacturing landscape is rapid prototyping. By leveraging advanced 3D printing, CNC machining, and other agile manufacturing techniques, companies can now create accurate, functional prototypes in a fraction of the time traditional methods require.

What Are Rapid Prototypes and How Do They Work?

Rapid prototypes are physical models of products created using advanced manufacturing technologies to quickly transform digital designs into tangible objects. These prototypes allow engineers, designers, and stakeholders to evaluate form, fit, and function before committing to large-scale production. Unlike traditional prototyping, which can take weeks or months, rapid prototyping significantly reduces lead times and accelerates product development cycles.

Key Techniques Used in Rapid Prototyping

| Technology | Description | Best Use Case | Lead Time |

|---|---|---|---|

| 3D Printing (SLA/SLS/FFF) | Builds prototypes layer by layer using resins, powders, or thermoplastics | Ideal for complex geometries and intricate details | 1–3 days |

| CNC Machining | Uses subtractive manufacturing to carve prototypes from solid blocks | Suitable for functional prototypes and high-precision parts | 2–5 days |

| Vacuum Casting | Creates multiple prototype copies using silicone molds | Perfect for small batch production and testing | 5–7 days |

| Sheet Metal Prototyping | Produces metal prototypes by cutting, bending, and forming thin sheets | Best for enclosures, housings, and structural components | 5–10 days |

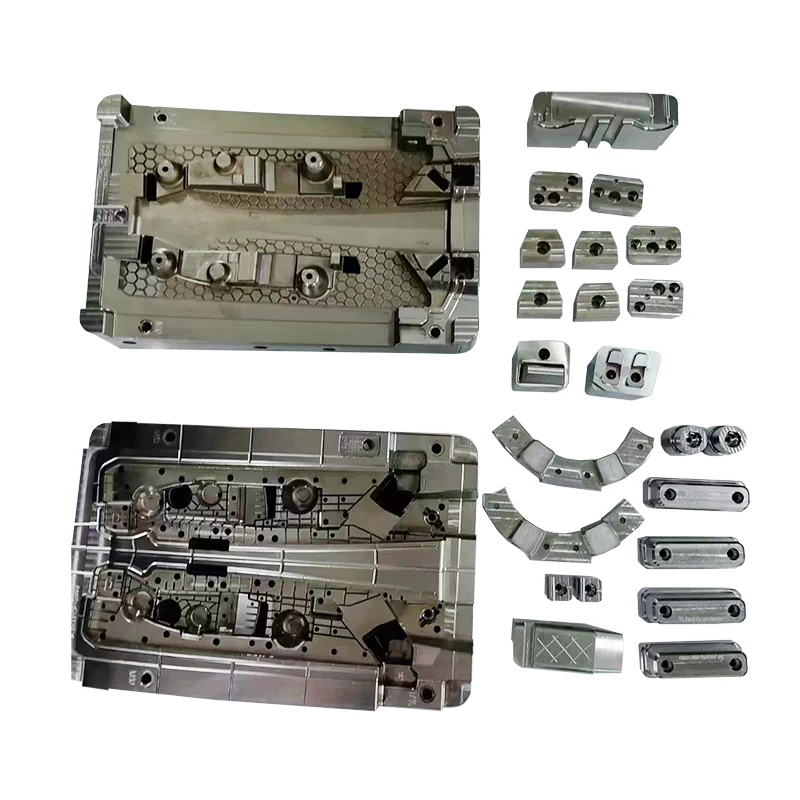

| Injection Molding | Uses aluminum or steel molds for low-volume production | Great for testing material performance and durability | 7–15 days |

How the Process Works

-

Concept Design – Designers create 3D CAD models to visualize the product.

-

Data Preparation – Files are optimized for manufacturing with necessary tolerances.

-

Prototype Fabrication – Using techniques like 3D printing or CNC machining, the prototype is created.

-

Testing & Evaluation – Engineers assess functionality, ergonomics, and aesthetics.

-

Iteration & Refinement – Modifications are made until the desired design is achieved.

This process ensures faster feedback loops, cost-effective validation, and improved collaboration between teams.

Why Are Rapid Prototypes Crucial for Product Innovation?

In a competitive global marketplace, innovation speed defines success. Rapid prototyping offers numerous advantages for companies across industries, including automotive, aerospace, consumer electronics, medical devices, and more.

Key Benefits of Rapid Prototypes

-

Accelerated Time-to-Market

Shorter lead times mean you can launch products faster than competitors. -

Early Design Validation

Prototypes allow engineers to test ergonomics, usability, and structural integrity early in the process. -

Cost Reduction

Avoid costly production errors by validating designs before mass manufacturing. -

Enhanced Customization

Rapid prototyping makes it feasible to produce highly customized solutions. -

Risk Mitigation

Identifying design flaws early reduces financial and operational risks. -

Seamless Collaboration

Tangible models improve communication between engineers, designers, and decision-makers.

Real-World Impact

Consider the case of consumer electronics: brands introducing wearables or smart home devices often rely on rapid prototyping to test ergonomics, heat dissipation, and assembly processes. By doing so, they save millions in retooling costs and shorten the time from concept to launch by months.

How to Choose the Right Rapid Prototyping Solution

Choosing the right rapid prototyping method depends on your project’s requirements, including material properties, dimensional tolerances, and functional performance.

Factors to Consider

-

Material Requirements

-

Do you need plastics, metals, composites, or elastomers?

-

-

Functional Testing Needs

-

Will the prototype undergo mechanical, thermal, or fluidic testing?

-

-

Surface Finish & Aesthetics

-

High-end consumer products may require smooth, polished finishes.

-

-

Budget & Timeline

-

Balancing speed and cost is key for choosing between 3D printing, CNC machining, or injection molding.

-

-

Batch Volume

-

For one-off prototypes, 3D printing may be ideal; for small production runs, vacuum casting or injection molding may be better.

-

Our Advanced Rapid Prototyping Capabilities

At Mudebao, we provide a comprehensive range of solutions tailored to your project’s unique requirements:

| Capability | Specification | Lead Time | Applications |

|---|---|---|---|

| 3D Printing | Up to 0.05 mm layer resolution | 1–3 days | Medical models, consumer electronics |

| CNC Machining | Tolerances up to ±0.01 mm | 2–5 days | Aerospace, automotive, industrial parts |

| Vacuum Casting | Replicates up to 50 parts | 5–7 days | Small batch production, market testing |

| Sheet Metal | Up to 6 mm thickness | 5–10 days | Enclosures, mechanical housings |

| Injection Molding | Low-volume runs of up to 1,000 pcs | 7–15 days | Functional product validation |

With our expertise, we ensure precision, reliability, and speed—helping clients gain a competitive edge.

FAQs About Rapid Prototypes

Q1: How long does it take to create a rapid prototype?

A: The lead time depends on the complexity, size, and materials involved. Simple 3D-printed prototypes can be produced in 1–3 days, while CNC machining or vacuum casting may take 5–7 days. For low-volume injection molding, the turnaround is typically 7–15 days.

Q2: What industries benefit most from rapid prototyping?

A: Virtually every industry can leverage rapid prototypes, but they are particularly valuable in:

-

Automotive – testing aerodynamic components and interiors

-

Aerospace – validating high-strength, lightweight parts

-

Medical Devices – producing anatomical models for testing

-

Consumer Electronics – optimizing ergonomics and assembly

-

Industrial Equipment – ensuring mechanical compatibility before production

In the era of digital manufacturing and global competition, rapid prototypes are no longer optional—they are a necessity for businesses striving to innovate and deliver products faster than ever before. By reducing development cycles, minimizing risks, and enabling cost-effective testing, rapid prototyping bridges the gap between concept and reality.

At Mudebao, we specialize in providing high-precision, fast-turnaround rapid prototyping solutions tailored to your specific needs. Whether you need a single functional prototype or a small production run, our advanced capabilities ensure unmatched quality and reliability.

If you’re ready to accelerate your product development process, contact us today to discuss your project requirements and discover how we can help bring your ideas to life.