- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

How Do Rapid Prototypes Transform Product Development?

2025-09-16

Innovation cycles are accelerating across industries, and companies are under constant pressure to bring products to market faster without sacrificing quality. Traditional product development cycles, which often required months or even years of design, testing, and revisions, are no longer practical in today’s highly competitive landscape. This is where rapid prototypes play a pivotal role.

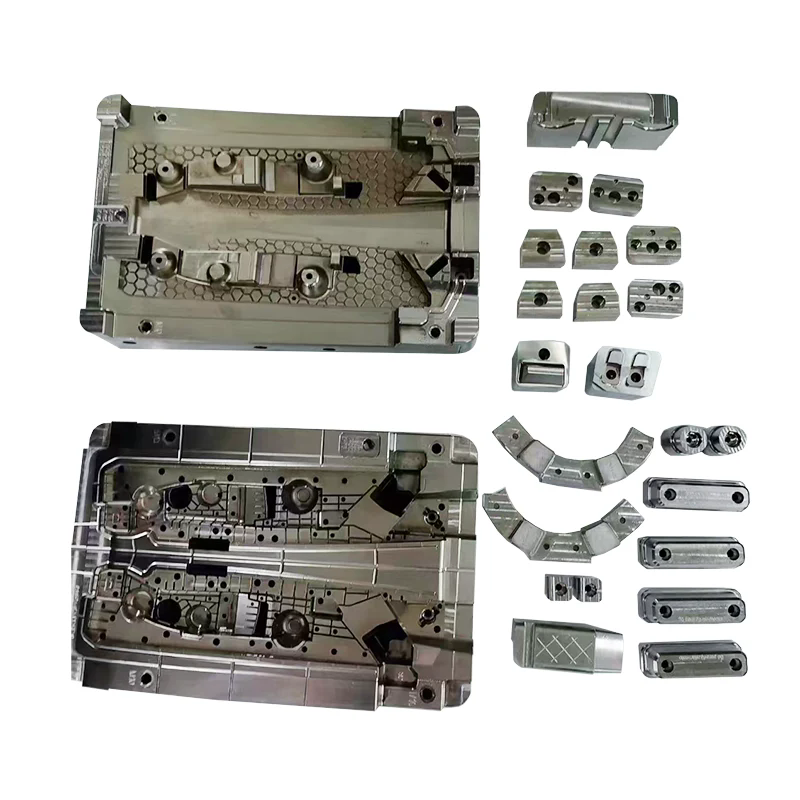

A rapid prototype is a physical or digital model created quickly from a design concept to evaluate form, fit, function, and usability. Unlike conventional prototypes, which can take weeks of machining, tooling, and assembly, rapid prototypes are typically produced in a matter of hours or days. This speed is made possible by advanced technologies such as 3D printing, CNC machining, injection molding, and vacuum casting.

The purpose of a rapid prototype goes beyond just visualization. Companies use prototypes to test ergonomics, identify design flaws, gather user feedback, and ensure that manufacturing methods are feasible before committing to mass production. In industries such as automotive, aerospace, medical devices, consumer electronics, and industrial equipment, the ability to validate designs quickly has become a competitive necessity.

Key benefits of rapid prototypes include:

-

Speed to market: Reducing design-to-production time dramatically.

-

Cost savings: Detecting errors early prevents costly redesigns later in the process.

-

Flexibility: Designers can iterate multiple times before finalizing a product.

-

Customer engagement: Tangible models make it easier to secure client approvals.

As a result, rapid prototyping has shifted from being a niche tool to becoming an integral part of mainstream manufacturing strategies worldwide.

What Technologies and Materials Define Rapid Prototypes?

While the term “rapid prototyping” is broad, the techniques used can be categorized into several major technologies, each with distinct advantages.

Primary Technologies for Rapid Prototypes

-

3D Printing (Additive Manufacturing)

-

Builds prototypes layer by layer from CAD models.

-

Suitable for complex geometries and quick iterations.

-

Common methods include FDM, SLA, and SLS.

-

-

CNC Machining

-

Produces prototypes by subtracting material from a solid block.

-

Offers high precision and is suitable for functional parts.

-

Compatible with a wide range of metals and plastics.

-

-

Vacuum Casting

-

Creates small batches of prototypes using silicone molds.

-

Ideal for replicating injection-molded parts at a lower cost.

-

Produces parts with excellent surface finish and durability.

-

-

Injection Molding for Prototyping

-

Provides realistic parts that are almost identical to mass-produced versions.

-

Costly for single pieces but valuable for pre-production validation.

-

-

Sheet Metal Prototyping

-

Used for enclosures, brackets, and industrial equipment.

-

Ensures structural integrity and functional testing.

-

Material Options for Rapid Prototypes

Depending on the method, prototypes can be created from a variety of materials:

-

Plastics: ABS, nylon, polycarbonate, polypropylene, resin.

-

Metals: Aluminum, stainless steel, titanium, copper alloys.

-

Elastomers: TPU, silicone, rubber-like materials for flexible parts.

The selection of technology and material depends on whether the prototype is intended for visual demonstration, functional testing, or pre-production validation.

Technical Parameters of Rapid Prototypes

| Parameter | Specification Range/Options |

|---|---|

| Lead Time | 1 – 10 days depending on complexity |

| Material Options | Plastics (ABS, PC, Nylon), Metals (Aluminum, Steel), Elastomers |

| Dimensional Accuracy | ±0.05 mm – ±0.2 mm depending on process |

| Surface Finish | Matte, polished, painted, anodized, textured |

| Batch Size | 1 – 1000 prototypes (depending on method) |

| Technology Used | 3D Printing, CNC Machining, Injection Molding, Vacuum Casting |

| Durability | From concept models to fully functional parts |

These parameters highlight how rapid prototypes are flexible enough to address multiple stages of the product lifecycle, from ideation to production testing.

What Factors Should Businesses Consider When Choosing Rapid Prototypes?

Deciding which rapid prototyping service or method to use is a critical step in ensuring a successful product launch. The right choice depends on the stage of development, budget, timeline, and end-use requirements.

Key Considerations in Rapid Prototyping

-

Purpose of the Prototype

-

Concept models: Focus on appearance and ergonomics.

-

Functional prototypes: Test mechanical performance and durability.

-

Pre-production prototypes: Validate manufacturing feasibility and compliance.

-

-

Material Properties

-

Select materials that mimic the final product as closely as possible.

-

Consider thermal resistance, strength, flexibility, and chemical compatibility.

-

-

Tolerance and Precision

-

For industries like aerospace or medical devices, tight tolerances are crucial.

-

Prototypes must match final production specifications to reduce iteration cycles.

-

-

Cost vs. Quantity

-

Low-volume runs may favor vacuum casting or 3D printing.

-

Higher-volume, production-ready prototypes may justify CNC machining or injection molding.

-

-

Timeline

-

Urgent projects benefit from additive manufacturing due to speed.

-

Projects requiring extensive testing may need hybrid approaches.

-

Benefits of Choosing the Right Rapid Prototyping Method

-

Reduced production delays caused by unforeseen design flaws.

-

Improved accuracy in market testing with realistic prototypes.

-

Enhanced collaboration between designers, engineers, and clients.

-

Increased confidence before making large-scale tooling investments.

Common FAQs About Rapid Prototypes

Q1: What industries benefit the most from rapid prototypes?

A: Almost every industry benefits, but the most prominent include automotive, aerospace, consumer electronics, and healthcare. For example, car manufacturers use rapid prototypes to test dashboard ergonomics, while medical companies create surgical tool prototypes to ensure safety and performance before mass production.

Q2: What is the difference between a rapid prototype and a production prototype?

A: A rapid prototype is built quickly to test and evaluate ideas, often with different materials than the final product. A production prototype, however, is designed to replicate the end-use product as closely as possible, both in material and manufacturing method. Businesses often use rapid prototypes early in the design process and production prototypes as they approach commercialization.

What Future Trends Will Redefine Rapid Prototypes?

The future of rapid prototyping is being shaped by technological advances, global supply chain pressures, and the growing need for sustainable manufacturing. Several trends are driving this evolution.

Emerging Trends in Rapid Prototyping

-

Hybrid Manufacturing: Combining additive and subtractive methods for greater efficiency.

-

AI-Integrated Design Tools: Advanced software enables faster, optimized designs ready for prototyping.

-

Sustainable Materials: Development of bio-based plastics and recyclable resins reduces environmental impact.

-

On-Demand Manufacturing: Prototyping services are increasingly offered globally, enabling distributed manufacturing and shorter lead times.

-

High-Performance Materials: Metals such as titanium and high-strength polymers are being used for functional prototypes in aerospace and defense.

Why Rapid Prototyping Will Continue to Dominate

In a fast-paced market, companies cannot afford long product development cycles. Rapid prototypes allow businesses to maintain agility, reduce risks, and stay ahead of competitors. Whether it is for validating a new smartphone design, ensuring compliance of a medical implant, or testing industrial machinery components, rapid prototyping ensures innovation remains practical and profitable.

At Mudebao, we are dedicated to providing advanced rapid prototyping solutions that meet the unique demands of industries worldwide. Our expertise in precision, materials, and scalable production ensures that every client receives prototypes aligned with their product vision and market goals. From concept modeling to pre-production validation, we deliver results that accelerate innovation and reduce costs.

For tailored solutions, bulk inquiries, or technical consultations, contact us today and discover how Mudebao can transform your product development cycle with world-class rapid prototyping services.