- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

News

What is Urethane Casting?

Urethane casting, also known as vacuum casting or polyurethane casting, is a versatile and cost-effective manufacturing and prototyping process. It involves creating parts by pouring liquid urethane into a mold, which then hardens into the desired shape. This method is particularly effective for pro......

Read MoreWhy Rapid Prototypes Are Revolutionizing Product Development

In today’s fast-paced market, Rapid Prototypes have become a game-changer for businesses looking to innovate quickly and efficiently. Whether you're in automotive, aerospace, medical, or consumer electronics, rapid prototyping accelerates design validation, reduces costs, and shortens time-to-market......

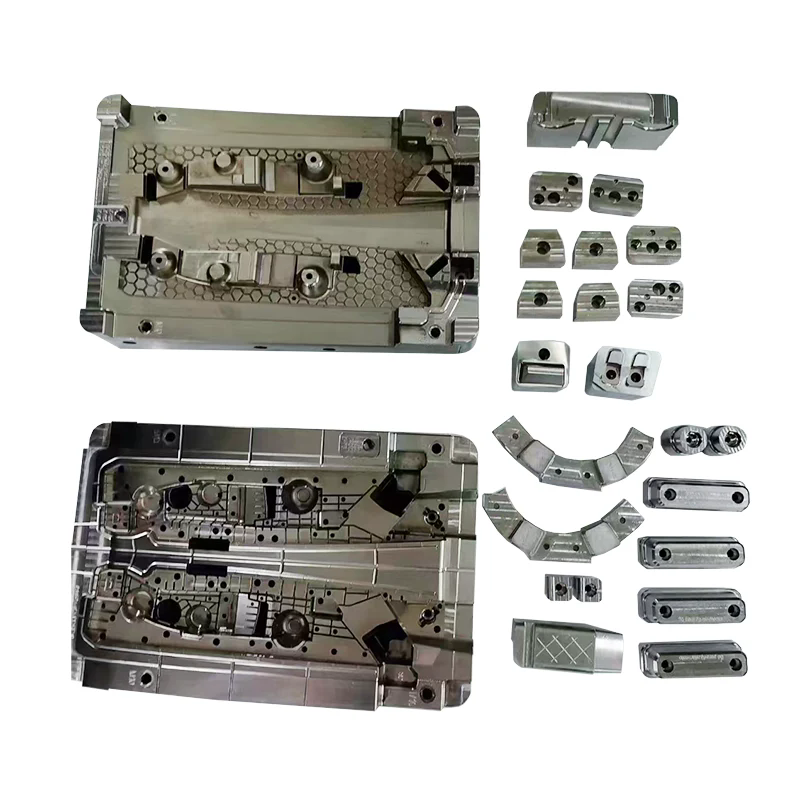

Read MoreWhat Will Happen If Moldbase And Standard Part Fail To Meet Quality Standards?

The moldbase is the base of the mold, and the mold core is used to be mounted on the mold base. The mold base facilitates the installation of the mold, serving as a key component for supporting, protecting, and connecting the mold.

Read MoreWhat is the difference between core and cavity?

The core and cavity include the mold cavity and the mold core, which are tightly combined to form the overall shape and internal structure of the mold. The mold cavity is primarily responsible for forming the product’s internal shape and structure and controlling the product’s precision. Conversely......

Read More